(Click on image to enlarge)

(Click on image to enlarge)

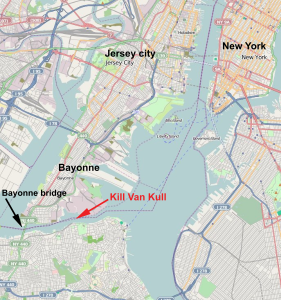

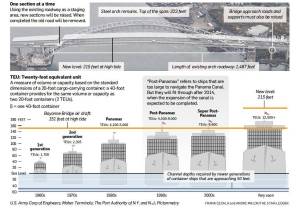

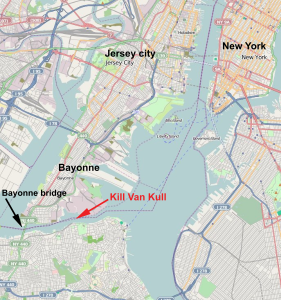

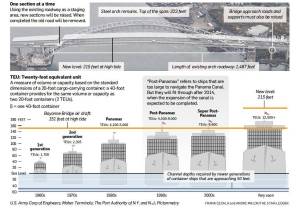

Incredible feets of engineering are being planned for at the $1 billion-dollar Bayonne Bridge height raising project, a project of the Port Authority of New York and New Jersey. Engineers plan to raise the road from 151 to 215 feet above the Kill van Kull while simultaneously keeping the bridge open to traffic, a measure some are calling “a Herculean feat of engineering and construction.” The project is required to accommodate larger container ships (especially those arriving after the widening of the Panama Canal in 2014) to ensure continued viability of the port industry, and raising of the roadbed is the quickest and cheapest solution to the clearance issue.

“It’s truly an exciting engineering project, by all means,” said Peter Zipf, the Port Authority’s chief engineer. “It’s a completely challenging project, and that’s an engineer’s delight. It’s coming up with a regional solution to a regional need.” As an engineering precedent, Zipf said the Bayonne project will be the first time a replacement roadbed is constructed above the old one, with traffic remaining open, before the original structure is removed.

(Click on image to enlarge)

(Click on image to enlarge)

According to nj.com, during construction, the two inner lanes will be closed to traffic and used as a staging area where a crane will likely be used to hoist a series of 84-foot-wide girders into place, forming the steel structure underpinning the new roadway. Like the original, the new roadbed will be suspended by steel cables from the bridge’s original 79-year-old arch. The two existing outer lanes will remain open, shielded from the work overhead, providing one traffic lane in each direction. To rise to the level of the higher roadbed, Zipf said the bridge approaches will be made slightly steeper and longer, constructed in a similar method from staging areas on the original approaches.

About the Bridge

When the $13 million Bayonne Bridge opened on November 15, 1931, at 1,675 feet it had become the longest steel-arch bridge in the world, an honor it held for the next 45 years.

—————————–

Thoughts on the engineering task ahead of them in maintaining traffic while raising the bridge? Thoughts on possible legal implications should the project not go as planned? Sign up for email delivery of the Blog’s posts to your inbox to learn the latest news concerning architects, engineers, designers, and other construction professionals.

——————————

Photo credits: Map via Wikipedia/Creative Commons License; Plan sketch via Frank Cecala & Andre Malok/The Star Ledger.